We provide realistic and practical solutions for conservation of energy.

Over 100 more than satisfied customers in last 4 years.

Let’s work together to maximize your profits by optimizing energy costs.

• Vodaluft Energy Technicks is a five year old company and has vast experience in energy conservation solutions. The company is certified by BEE as energy auditors who are capable of giving best solutions to customers at minimal cost.

• Pumps Efficiency & Performance

• Air Conditioning Units Performance

• Fans & Blowers Efficiency & Performance

• Air Compressors Efficiency & Performance

• Refrigeration Compressors Efficiency & Performance

• Cooling Towers Efficiency & Performance

• Heat Exchanger Performance

• Steam Turbines Efficiency & Performance

• Electrical Motors Efficiency

• Waste Heat Recovery Efficiency & Performance

• Waste Heat Recovery Efficiency & Performance

• Boilers Efficiency & Performance

• Thermopacs & Thermic Fluid Heaters Efficiency

• Furnaces & Ovens Efficiency & Performance

• Steam Trap Performance Assessment

•The basic aim of the audit is to conduct energy audit by an accredited energy auditor in line with Bureau of Energy Efficiency standard as stipulated in the rules governing the mandatory audit.

1.Brief writeup of manufacturing process

2.Process flow diagram and major power consuming equipment

3.Raw material inputs, quantity & costs

1.List of utilities

2.Brief description of utility

a.Steam

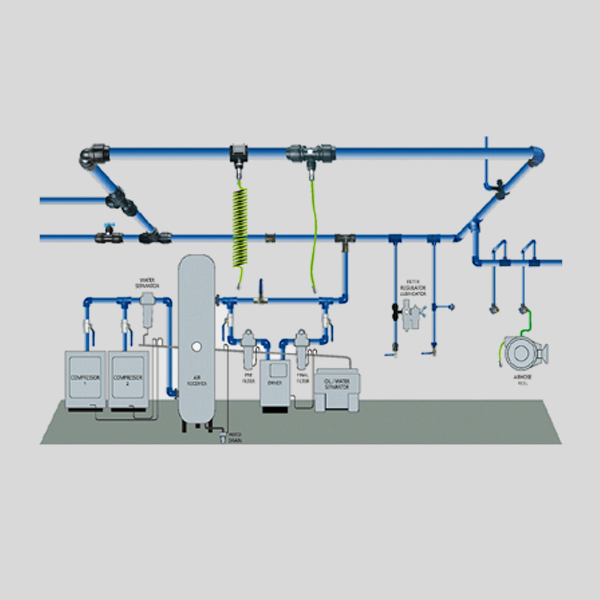

b.Compressed Air

c.Cooling Water

d.Chilled Water

e Water

f.Electricity

g.Others

1. Energy balance of the designated consumer in tabular form

2. Flow Chart showing flow rate, temperature & pressure of all input / output streams

3. Water balance for entire industry

1.List of equipments & processes where performance testing was done

2.Results of performance testing

1. Cooling water system performance assessment

2. Furnace / kiln efficiency analysis

3. Refrigeration system performance assessment

4. Electrical motor load analysis

5. Specific Energy Consumption

6. Boiler Efficiency Assessment

7. Lighting system

8. Thermic fluid heater performance assessment

9. Diesel generator set performance assessment

10. Compressed air system performance assessment

11. Others

1. Benchmarking

2. Conform to acts, rules and regulations framed thereunder

3.Strength and weakness of the designated consumer

4. Training of staff responsible for operational & associated processes

5.General audit review

6. Energy management monitoring system

7. Energy management policy

8. Training of staff responsible for operational & associated processes

1.The report shall provide existing energy profile of the designated consumer with percentage share of major equipments, process, utilities so that it becomes a basic document for future monitoring

2.Details of energy conservation measures recommended in Form 2

3.Cost benefit analysis of each recommended energy saving measures as per the standard practice

4.The investment proposals shall be backed with technical and economic viability and prioritization on energy conservation measures based on financial analysis of various options taking in to account the capacity of the designated consumer to make investment in such measures.

5.The energy auditor may also consider the substitutions of existing energy use by any other form of techno-commercially viable form of energy 6.Details of energy saving measures implemented, investment made and saving in energy achieved together with progress made in the implementation of the remaining energy saving measures in Form 3.

The report shall be prepared in the required formats and as per the guidelines and duly signed by an Accredited Energy Auditor.

Corporate Social Responsibility :

We are committed to conduct energy saving studies in at least one non profit organization free of cost.

Training programe :

We commit to save energy in companies and help them to earn more profit.

Help companies conserve energy and water.